Stainless Steel Solenoid Valve

Type "JR" Reduced Port

Normally Open - 3/8" to 1/2" Pipe Size

Fluid Temp: -350°F to 400°F | Max. Static Pressure - 300 PSI

No Differential Pressure Required to Open

Operation

This solenoid valve closes when energized and opens when de-energized. In this direct acting valve, when the coil is energized, the stem is pressed into its conical seat by the plunger.

Application

To control the flow of Steam, Hot Liquids, Hot Gases, Cryogenics** and any other fluids not reactive with construction materials and free of sediment. Cryogenic fluids include liquid oxygen (-297°F), liquid argon (-30°F) and liquid nitrogen (-320°F). This solenoid valve operates from zero to maximum differential pressure indicated in table. Valve must be mounted in horizontal pipe with solenoid enclosure vertical and on top.

**Cleaning:

Cryogenic valves are degreased and cleaned to keep them free of moisture

Oxygen valves are also "black light" tested

- Specifications

- Construction

|

Pipe Size Inches |

Max. Diff. PSI |

Valve Port Size | Type No. |

Watts AC |

Amps Hold 120-60 |

Amps Inrush 120-60 |

Watts DC |

Ship Wt. Lbs. |

Dimension In Inches | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

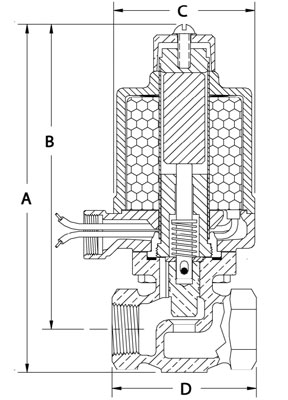

| A | B | C | D | |||||||||

| 3/8 | 23 | 3/8 | 10JR21 | 25 | 0.5 | 1.4 | 18 | 7 | 7 | 6-1/4 | 2-7/8 | 2-3/4 |

| 70 | 3/16 | 10JR51 | ||||||||||

| 135 | 1/8 | 10JR61 | ||||||||||

| 45 | 3/8 | 25JR21 | 45 | 1.0 | 2.6 | 23 | 10 | 7-7/8 | 7-1/8 | 3-1/2 | 2-3/4 | |

| 135 | 3/16 | 25JR51 | ||||||||||

| 300 | 1/8 | 25JR61 | ||||||||||

| 1/2 | 23 | 3/8 | 10JR22 | 25 | 0.5 | 1.5 | 18 | 7 | 7 | 6-1/4 | 2-7/8 | 2-3/4 |

| 70 | 3/16 | 10JR52 | ||||||||||

| 135 | 1/8 | 10JR62 | ||||||||||

| 45 | 3/8 | 25JR22 | 45 | 1.0 | 2.7 | 23 | 10 | 7-1/8 | 7-1/8 | 3-1/2 | 2-3/4 | |

| 135 | 3/16 | 25JR52 | ||||||||||

| 300 | 1/8 | 25JR62 | ||||||||||

(* Wetted parts)

*Valve Body - 304 Stainless Steel Globe Pattern - NPT ends

Coil Enclosure - Malleable Iron, 1/2” NPS conduit conn.

*Plunger - 430 Stainless Steel

*Poppet - 304 Stainless Steel

*Stem - 303 Stainless Steel

*Bonnet Tube - 304 Stainless Steel

*Spring - Inconel

*Body Seal - Non Asbestos Gasket

*Orifice Seal - Metal to Metal

*AC Shading Coil - Silver

*Stem Pin - Inconel

Coil - Encapsulated Class H, 18” leads

Website

Website