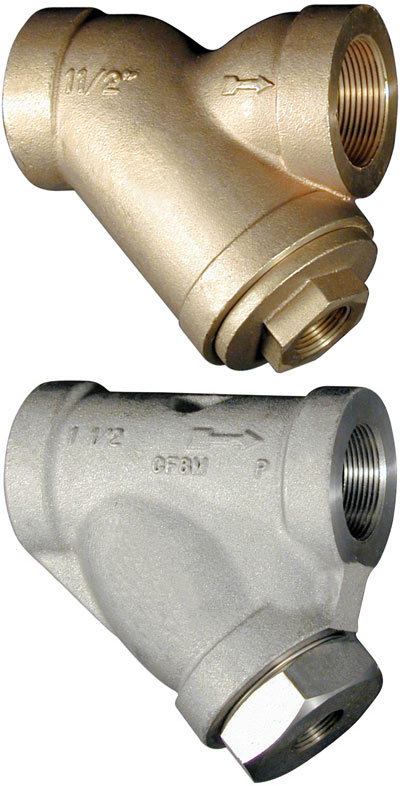

Bronze and Stainless Steel

Strainers

Application

The presence of foreign particles in an automatic valve may seriously affect its dependability. The installation of a strainer close to the inlet side of the valve is the best means of preventing the entrance of pipe chips, scale, rust, pipe dope, welding slag or sediment into the valve, provided the screen is periodically removed for cleaning.

Cleaning for Cryogenix & Oxygenic Service

- Strainers for Cryogenic applications are degreased and cleaned to keep them free of moisture.

- Strainers for Oxygen service are degreased and cleaned then "black light" tested.

- Specifications

- Construction

Bronze 1/4" to 3" Pipe Size

|

Pipe Size Inches |

Screen Size | Type No. |

Ship Wt. Lbs. |

Dimension In Inches | ||

|---|---|---|---|---|---|---|

| A | B | C | ||||

| 1/4 | 60 Mesh 0.009 Openings | BR 0 | 3/4 | 2-3/4 | 2-1/4 | 1/4 |

| 3/8 | BR 1 | 3/4 | 2-3/4 | 2-1/4 | 1/4 | |

| 1/2 | BR 2 | 3/4 | 2-3/4 | 2-1/4 | 1/4 | |

| 3/4 | BR 3 | 1-1/2 | 3 | 2-9/16 | 3/8 | |

| 1 | BR 4 | 2-1/4 | 3-3/4 | 2-3/4 | 3/8 | |

| 1-1/4 | 0.16 Diameter Perforations Lined with 30 Mesh | BR 5 | 3-1/4 | 4-7/16 | 3-5/8 | 3/4 |

| 1-1/2 | BR 6 | 4-1/2 | 4-15/16 | 3-7/8 | 3/4 | |

| 2 | BR 7 | 7 | 6-1/8 | 5-1/16 | 1 | |

| 2-1/2 | BR 8 | 12-1/2 | 8-1/4 | 6 | 1-1/4 | |

| 3 | BR 9 | 18 | 9 | 6-3/4 | 1-1/2 | |

Stainless Steel 1/2" to 2" Pipe Size

|

Pipe Size Inches |

Screen Size | Type No. |

Ship Wt. Lbs. |

Dimension In Inches | ||

|---|---|---|---|---|---|---|

| A | B | C | ||||

| 1/2 | 60 Mesh 0.009 Openings | SS 2 | 1-1/2 | 3 | 2-3/8 | 1/4 |

| 3/4 | SS 3 | 2-1/4 | 3-3/4 | 2-13/16 | 3/8 | |

| 1 | SS 4 | 3-1/4 | 4-5/8 | 3-1/8 | 3/8 | |

| 1-1/2 | 0.16 Diameter Perforations Lined with 30 Mesh | SS 6 | 6-3/4 | 5-5/8 | 4-3/4 | 3/4 |

| 2 | SS 7 | 11-1/2 | 7 | 6 | 1 | |

Pressure Temperature Ratings

| Material | Steam | Liquids |

|---|---|---|

| Bronze | 300 PSI @ 350°F | 400 PSI @ -20 to 150°F |

| Stainless Steel | 845 PSI @ 750°F | 1,440 PSI @ 100°F |

Strainer bodies have screwed ends. Screens are stainless steel with opening sizes as listed in tables below. Other sizes can be furnished upon request. Liberal straining area provides for fluid passage at minimum pressure drop. Screens are easily removed for cleaning. Strainers are furnished with NPT blow off connections unplugged. See charts below for blow-off sizes (C Dim.)

Website

Website